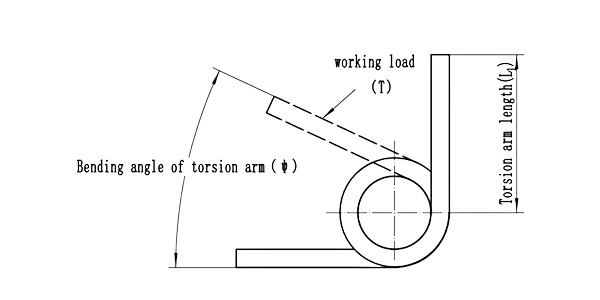

A torsion spring is a spiral spring that stores energy by twisting around its axis. It usually has fixed arms or hooks at both ends to transmit torque. It is mainly used in scenarios that require rotational reset, angle control or torque maintenance.

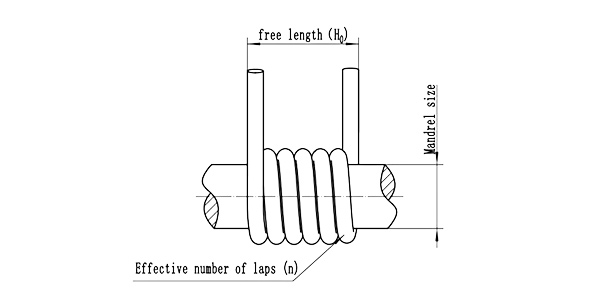

Technical Parameters

- Wire diameter d (mm): spring wire diameter

- Outer diameter D2 (mm): spring outer diameter

- Expanded length L0 (mm): spring expanded length

- Angle Deg (°): original angle between torsion pins

- Number of turns Na (turns): total number of turns of the spring

- Direction of rotation: left/right

- Strength requirements: elastic performance, other technical requirements, etc.

Features

- Precise torque output: ±3° angle tolerance can be designed to ensure rotational reset accuracy.

- Fatigue resistance: Titanium alloy material still maintains 90% of initial torque after 10⁷ cycles.

- Space efficiency: Compact spiral structure adapts to narrow installation space.

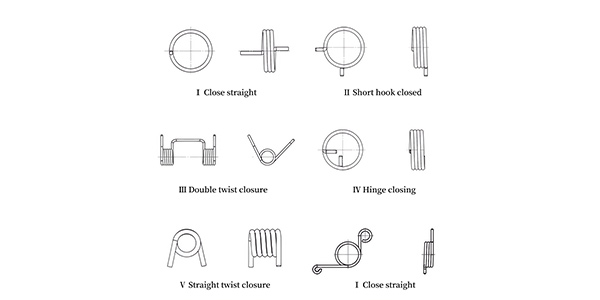

Tips for Customizing Torsion Springs

- Wire diameter range: φ0.08mm~φ4.0mm

- Technical standards: Conventional products refer to national standards and industry standards; customized products are subject to the final technical standards and technical drawings confirmed by the customer

- Material: Carbon steel (SWC), Alloy steel, (SEA9260/ 9254/ 6150/ SUP9/ SUP10/ SUP12 /51CrV4), stainless steel, music wire/piano, wire (SWP), etc.

- Surface treatment: Ep.Zn8.c2C, Ep.Cd5.c2C, Ap.Ni5, Ep.Cr5hd, Ct.p, Ep.Sn5, Ct.o, Custom

Applications

Industry/automobile/motorcycle/electronics/toys/sports/mechanical equipment/UAV, etc., providing energy storage and reset functions.